Pieralisi Continuous Olive Oil Plants

The continuous plant comprises a set of matching machines in a uniform production line that is organised rationally and technologically advanced. Find out more about the processing performed by Pieralisi plants.

Pieralisi’s sophisticated separation technologies offer specific solutions for the majority of liquid separation and extraction processes.

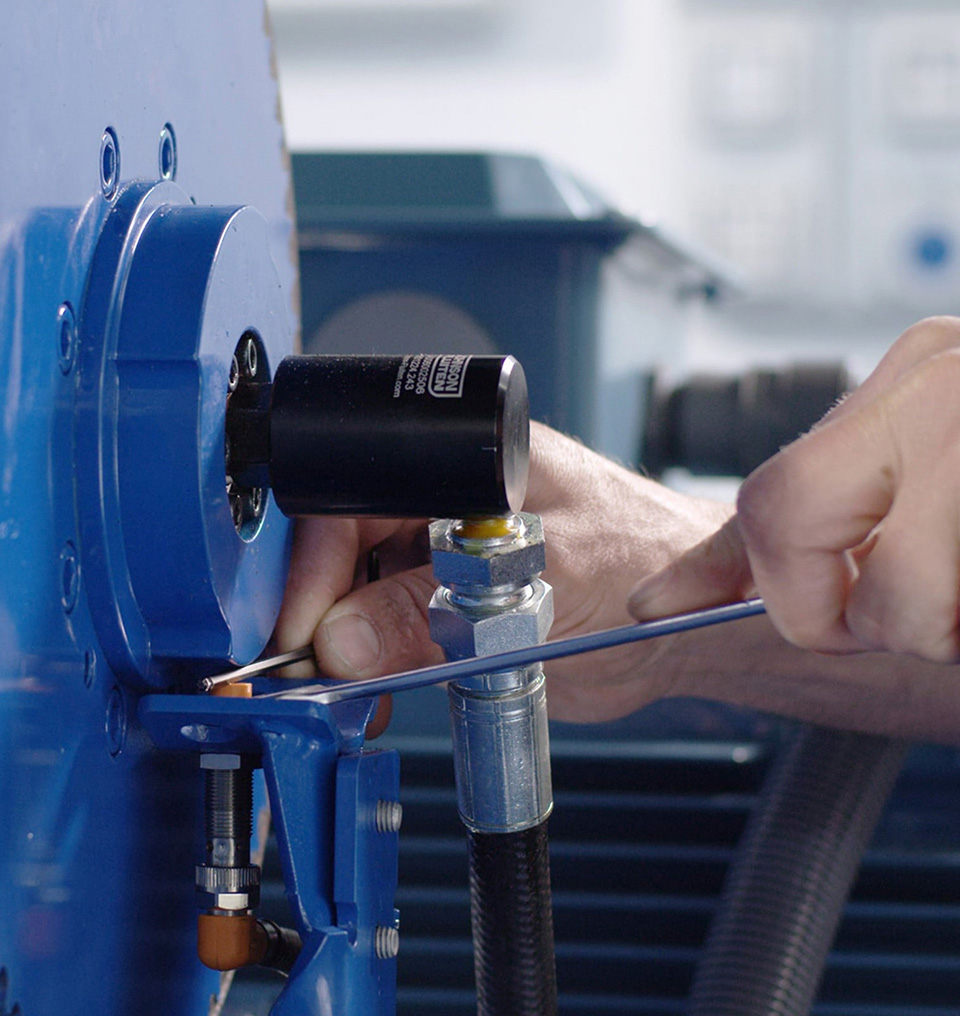

Thanks to a network of impeccably trained specialist technicians at national and international level, we ensure our plants and machinery run like clockwork, to achieve ever-increasing performance levels.

Pieralisi offers a comprehensive range of customer service schemes and maintenance plans designed to prevent and solve any inconveniences that may arise during normal machinery wear.

Pieralisi’s state-of-the-art technologies offer specific solutions for multiple application sectors. From protecting the environment to recovering mineral fuels and lubricants, from treatment processes for drilling mud and recycling industrial fluids to all stages of olive oil processing.